Mechanical Installation Coordinator

EuroSort 's-Graveland

What is required?

- Completed higher vocational education in mechanical engineering or completed lower vocational education in mechanical engineering supplemented by work experience in the machine building industry

- Knowledge of ERP systems (Ridder iQ)

- Excellent command of Dutch and English, both verbally and in writing, additional language knowledge is a plus

- Independent, solution-oriented and able to set priorities

- Positive, eye for detail and able to work well together

- In possession of own transport

What will you get?

- €3.000 - €4.500 gross p/m (depending on knowledge and experience)

- 32 to 40 hours working week

- 30 holiday days

- Possibility to enroll in training and courses

- Working from home opportunities, bonus scheme, laptop and telephone

- Daily fresh fruit, Friday afternoon drinks, monthly company lunch

What will you do?

- 60% Coordinating and supervising the assembly process

- 20% Making schedules

- 10% Internal consultation

- 10% Implementing process improvements

This vacancy has been created based on interviews with employees to help you get a realistic preview of the job.

Ask a question directly

Recruitment team

Vacancy

Acquisition based on this advertisement is not appreciated. We usually fill the vacancies ourselves and in exceptional cases we work with preferred suppliers

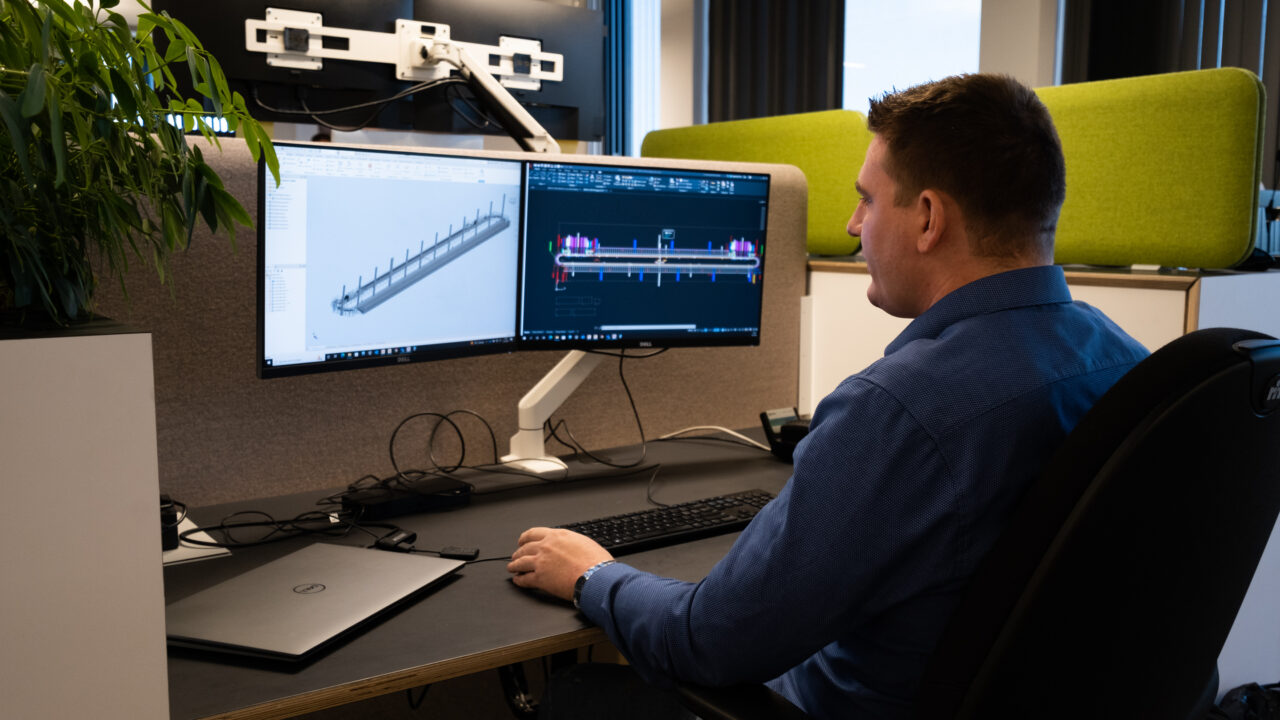

As a Mechanical Installation Coordinator at EuroSort you are responsible for coordinating, supervising and controlling the entire assembly process of a sorting machine. When a project has been brought in, you look together with the Project Manager what the planning will look like and what is needed for the assembly process. You ensure that there is sufficient staffing of mechanics and make sure that all the necessary materials are on site. You also make the technical installation plan and the specific work instructions for the parts that need to be assembled.

During the actual installation of the machine, you are the first point of contact for the mechanics on site. You offer technical support in case of ambiguities; consult with draftsmen and send missing parts. You keep a close eye on the progress of the project and adjust the planning where necessary. You record the points for improvement that are reported during the assembly process in the appropriate systems. You implement improvements in the work process partly on the basis of this.

You are part of the installation team, which consists of two other Mechanical Installation Coordinators and an Electrical Installation Coordinator. You also work a lot with Project Managers. You are accountable to the Project Manager.

If you like being the connecting factor between field mechanics and internal colleagues and find it challenging that you sometimes have to solve problems under time pressure, then this is the job for you.

Working week

On an enjoyable working day, I can directly help the onsite mechanics and internal colleagues with their technical questions and think along with them about process improvements and the company’s direction.

On a less enjoyable day, there are multiple problems on site that cannot be solved immediately, slowing down the process.

- 07:00

- 08:00

- 09:00

- 10:00

- 11:00

- 12:00

- 13:00

- 14:00

- 15:00

- 16:00

- 17:00

- 18:00

-

- Lunch

- Updating mail

- Planning

- Call with Mechanic

- Fixing mounting problems

- Adjusting the planning

- Consultation with the draughtsman

- Sending materials

- Updating mail

- Updating mail

- Consultation with Shipping Officer

- Call with Mechanic

-

- Lunch

- Project meeting

- Call with Mechanic

- Fixing mounting problems

- Sending materials

- Call with Mechanic

- Implementing process improvement

- Adjusting the planning

- Call with Mechanic

- Updating mail

-

- Lunch

- Project meeting

- Updating mail

- Consultation with the draughtsman

- Adjusting the planning

- Consultation with Transport

- Sending materials

- Updating mail

- Call with Mechanic

- Updating mail

-

- Lunch

- Sending materials

- Planning

- Fixing mounting problems

- Call with Mechanic

- Implementing process improvement

- Fixing mounting problems

- Updating mail

- Thinking about process improvement

-

- Lunch

- Project meeting

- Updating mail

- Consultation with the draughtsman

- Fixing mounting problems

- Consultation with Work Planner

- Implementing process improvement

- Updating mail

- Drinks

- Call with Mechanic

Firsthand experience

Growth

EuroSort considers personal development very important. That's why there are many opportunities to attend education, training and courses. At the moment EuroSort is developing a training policy to make this more concrete.

Working at EuroSort

EuroSort B.V. is specialised in the development and assembly of high volume sorting systems for various applications. Think of order processing, returns, counting and sorting by size, colour, type of products, e-commerce and cross docking. The company was founded in 2001 and believes in qualitative simplicity. Therefore, the sorting solutions are always simple, robust and made of high quality materials and components. This combination creates a system that optimises the work process and makes it more efficient, saves valuable floor space and improves and increases productivity.

- Founded in 2001

- Headquarters in 's-Graveland

- Globally active, branches in the Netherlands, Spain and North America

- 180 employees

- Average age 45 years

- Hybrid working in office positions

- Safety workwear is mandatory in the warehouse and is provided by EuroSort